Home » Resources » Application Notes » Planar Transformer Guide

Planar transformers are innovative magnetic components that provide electrical isolation, voltage transformation, and energy transfer functions in a compact form factor. This guide explores iNRCORE’s planar transformer offerings, their construction, applications, and key design considerations.

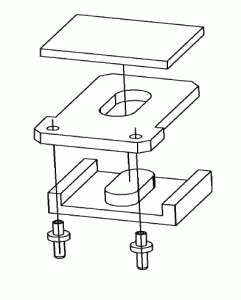

A planar transformer is a flat, low-profile transformer fabricated using printed circuit board (PCB) technology. Unlike traditional wire-wound transformers, planar transformers utilize etched copper windings on a multi-layer PCB substrate, allowing for a more compact design with enhanced performance characteristics.

Planar transformers consist of several key components:

| Parameter | Planar Transformer | Wirewound Transformer |

|---|---|---|

| Construction | Windings etched as tracks on PCB | Windings made from insulated wires |

| Core | PCB dielectric material | Ferrite, iron alloys, etc. |

| Size | Extremely compact and low profile | Larger, significant height |

| Leakage Inductance | Very low due to tight coupling | Higher due to poorer coupling |

| Parasitic Capacitance | Low as limited overlapping area | High due to more overlapping wires |

| AC Resistance | Low as wider copper tracks | Higher due to thinner winding wires |

| Turns Ratio Range | Typical 1:1 to 1:5 | Wide – 10:1 or more |

| Power Levels | Lower – less than 10W usually | Higher power handling capacity |

| Cost | Lower due to PCB process | Higher labor for hand winding |

| Integration | Excellent, embed directly to PCB | Moderate, but requires mounting |

| Repeatability | Very consistent and controlled | Poorer tolerance and unit-unit variation |

| Efficiency | >90% in well designed planar transformers | >95% in conventional transformers |

Planar transformers are utilized in various applications across different industries:

iNRCORE offers a range of planar transformers designed for optimal performance:

iNRCORE provides a comprehensive range of planar transformers suitable for various applications:

When choosing a planar transformer for your application, consider the following factors:

iNRCORE’s planar transformers provide efficient solutions for compact power conversion needs across various industries. With their innovative design, high efficiency, and versatility, our planar transformers are ideal for modern electronic systems requiring optimized performance in limited spaces.

For assistance in selecting the right planar transformer for your application or to discuss custom solutions tailored to your specific needs, please contact our experienced sales and engineering team. We are committed to helping you optimize your designs for peak performance and reliability while meeting your unique application requirements.

iNRCORE excels in creating application-specific designs for unique requirements. Our extensive capabilities in design, development, production, and testing allow us to deliver tailored solutions that meet your specific needs.

For questions about our application notes or to discuss custom products, please contact our team of experts. We’re here to help you find the perfect solution for your electronic component needs